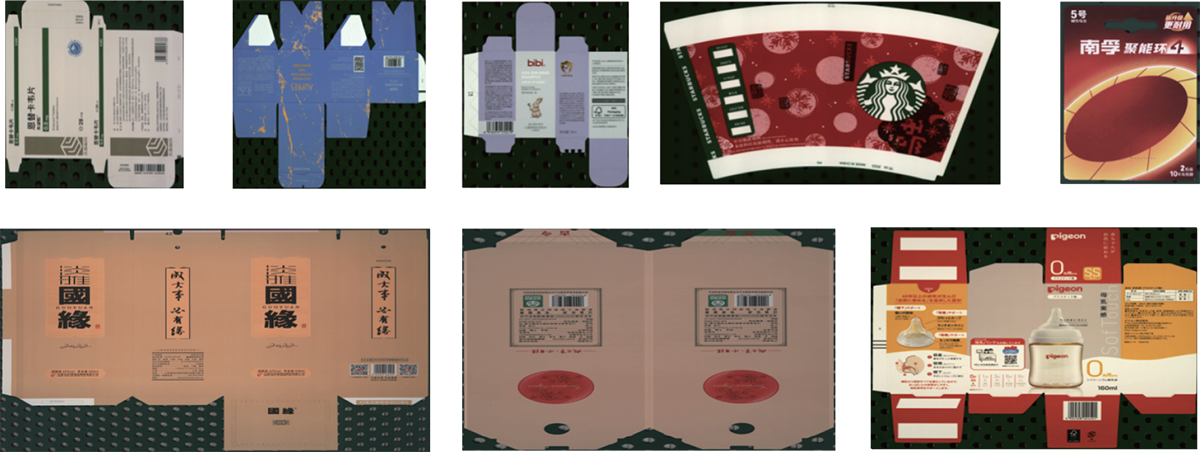

It is suitable for the surface quality inspection of die-cutting small-sheet social packages, which can be operated by a single person and realize the quick switching of offline quality inspection and box gluing mode through modularization to greatly reduce the labor. The system is suitable for wine bags, high-end cosmetic boxes, daily chemical tags, fan-shaped boxes and other products, through efficient and accurate automated inspection, to ensure the consistency and stability of product quality, effectively improve production efficiency, reduce costs and increase efficiency.

PRODUCT

The ultimate in simplicity with a single player:

With the automation device of loading, transferring, kicking off and collecting materials, it realizes one-key switching of different products, and the consistency and stability of product debugging is achieved by formulating and calling

With vertical palletizing and receiving, the good and bad product return line can be easily operated by one person

High-speed detection for ultimate efficiency

Maximum inspection speed is 400 meters/minute, matching with the speed of the gluer to ensure the production capacity

With the negative pitch function, it can increase the production capacity by 30% compared with the conventional quality inspection machine

Accurate detection, ultimate peace of mind

Layered process detection algorithms to achieve independent and accurate detection of color, variable information drawing, ink skin, registration, hot stamping, etc

Patented light column paper shielding technology and light source program control, effective response to the light column laser paper, gold and silver cardboard and other scenes, reduce false detection

Optional integrated device for the whole machine can effectively reduce dust false alarms and improve detection accuracy

Efficient Modeling, Ultimate Ease of Use

PDF, AI one-click modeling, new products within 3 minutes to complete the wizard-style modeling, easy

SPECIFICATION

- Maximum detection speed 400 m/min ‘

- Maximum inspection size (length*width) 630mm*300mm

- Minimum inspection size (length*width) 70mm*90mm

- Paper weight 150g/mm²-450g/mm²

- Minimum spot detection size (dirty, ink spots) 0.2mm² (Contrast ratio >20DN)

- Minimum line detection size (wire pulling, etc.) width ≥0.15mm,width ≥5mm

- Color difference detection △E≥3

- Overprint detection ±0.15mm

- Floor space size (length*height*width)

- Glued box connecting pattern: 530cm×250cm×150cm

- Fish scale offline mode: 680cm×250cm×150cm

- Reflow line model: 1250cm×350cm×150cm

- Total Weight 4000kg

- Gas requirements 0.8Mpa 0.8m³/min

ADAPTAION