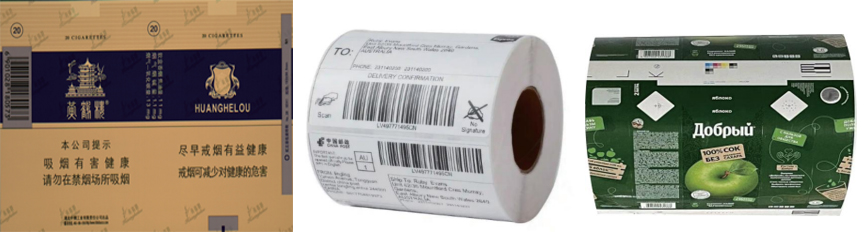

It is a printing quality visual inspection equipment mainly developed for roll materials. It can be adapted to self-adhesive labels such as cigarette packs and soft packages, electronics, daily chemicals, food, etc., to realize automatic detection of roll printing quality and improve factory quality

PRODUCT:

High-speed detection for ultimate efficiency:

Maximum inspection speed of 280 meters per minute for high productivity.

Adopting servo drive control, BST guiding device, closed loop tension control

Thecan be combined with a defect review machine to maximize productivity. The XTI520681 can be combined with a defect checker to maximize productivity.

Accurate stopping, precise control:

Specialized counting + metering defect location calibration recognition system, stopping accuracy within 15mm (also for PVC and PE materials).

Accurate detection, ultimate peace of mind:

Refined layering process detection algorithms to achieve independent and accurate detection of printing, knife line, color, overprinting, variable information, and so on.

Patented light column paper shielding technology and light source program control, effective response to light column laser paper, gold and silver cardboard and other scenes.

Masking algorithm can effectively deal with the products with variable background and reduce the false detection.

Efficient Modeling, Ultimate Ease of Use:

AI one-click modeling, wizard-like modeling of new products in 3 minutes, easy to operate.

SPECIFICATION

- Maximum detection speed 280 m/min

- Paper weight 0.1mm-0.4mm 100g/mm²-200g/mm²

- Tension range 10N-150N automatic control

- Maximum roll diameter 750mm

- Minimum spot detection size (dirty, ink spots) 10N-150N automatic control

- Minimum line detection size (wire pulling, etc.) width ≥0.1mm,width ≥5mm

- Color difference detection △E≥3

- Overprint detection ±0.1mm

- Floor Space Dimensions (length*height*width) 2500mm×1000mm×1800mm

- Total Weight 1600kg