Technical Specifications

- Equipment name FS Mark 500/FS Mark 650

- Maximum detection speed of 300 meters per minute

- Maximum detection size (length * width) 480mm * 420mm/630mm * 480mm

- Minimum detection size (length * width) 90mm * 90mm/90mm * 90mm

- Paper weight: 150g/mm ² -450g/mm ²/150g/mm ² -450g/mm ²

- Minimum point detection size (dirt, ink dots) 0.15mm ² (contrast>20DN)/0.2mm ² (contrast>20DN)

- The minimum line detection size (such as pull lines) is ≥ 0.12mm in width, ≥ 5mm in width/≥ 0.15mm in width, and ≥ 5mm in width

- Color difference detection △ E ≥ 3/△ E ≥ 3

- Overprint detection ± 0.1mm/± 0.15mm

- Floor size (length * height * width) 7750mm × 3150mm × 2300mm/8300mm × 3250mm × 2300mm

- Whole machine weight 4000kg/4500kg

- Gas source requirement 0.8Mpa/0.8Mpa

Equipment Advantages

- Cigarette/pharmacy whole process defects checking, support Variable data inspection

- Whole line can work integratly also support working each machine separately

- Latest FS-LIGHTING software, Automatic create template, easily study, more efficient

- Multi spectra color measure with double reject collection bin to realize color sorting

- Highest speed 120000pieces/hour, two staff working, connection package, saves labor cost

- Auto binding machine connect inspection machine, also can working separate by manual loading

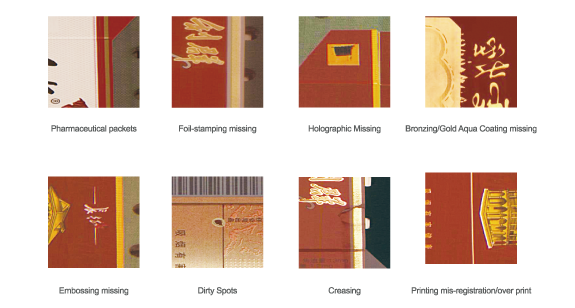

Product defect marking diagram

Application industry

Cigarette

packets