FS-FALCON Big Size Offline Rewinder Inspection System

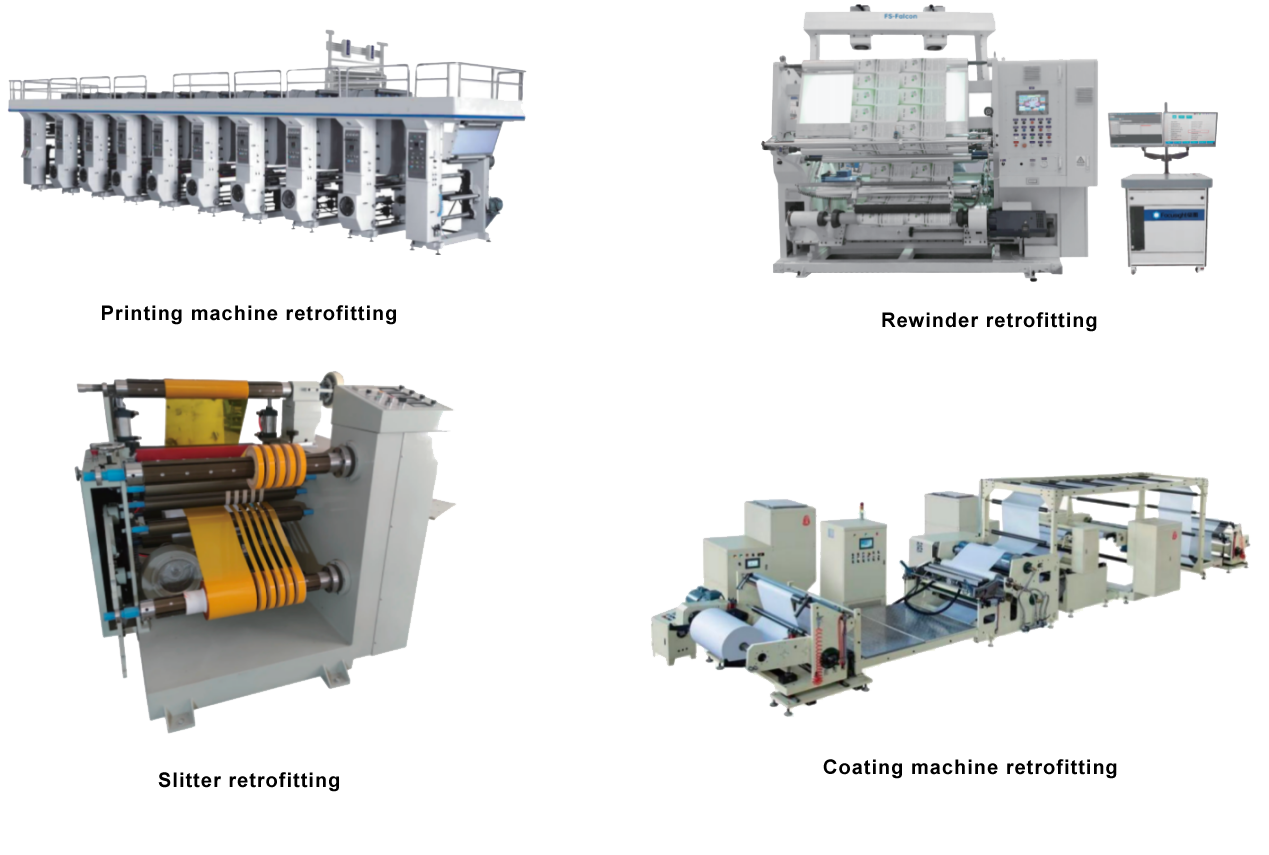

It is suitable for surface quality inspection of web packaging and printing products, realizing high-precision, automated real-time inspection of different web widths, timely detection of ink spots, dirty plates, knife lines, color difference, foreign matter and other defects, ensuring product quality consistency, eliminating material waste and reducing production costs. It is suitable for on-line printing, laminating, coating, laminating, slitting, off-line large rewinding, small rewinding detection/rejection and other scenes.

Product:

Efficient Modeling, Ultimate Ease of Use:

Rapid modeling based on a single specimen, no training required (as opposed to continuous templates), wizard-like system setup, modeling time less than 1 minute.

Online parameterization allows 10 levels of adjustment for all detection forces, which can be individually stored and recalled.

Different privileges can be granted to different users. There are three levels: administrator, manager, and operator, and the operation can be traced back.

High-speed detection for ultimate efficiency:

Regular 350 meters, up to 550 meters/minute real-time 1:1 distortion-free detection

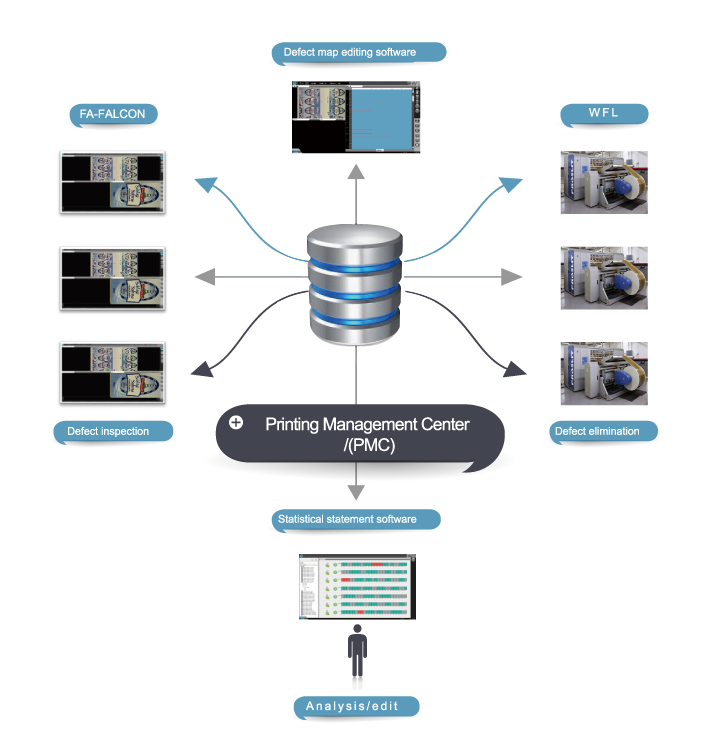

Defect data transfer call via scanning gun/variable code labels

Defect maps can be edited, filtered, merged, deleted, confirmed

The rewinder can be controlled by metering + counting to stop the defects accurately at the specified position, with a stopping deviation of ± 50 mm

Accurate detection, ultimate peace of mind:

Job Ref module, PDF and the first sample of the proofreading, to avoid printing plate and ink blending errors

Stand-alone Sub-Pixel Filament Detection Module

Stand-alone Module for Tiny Character Detection

Color Difference Measurement Module: Built-in 8 color standards, simultaneously monitor up to 30 measurement points, and output real-time data of dL, dA, dB, DE, color deviation trend and automatic warning or alarm

Real-time version of the circumference measuring module RLT, measuring accuracy of 0.1 mm

Powerful report analysis tools:

Inspection information can be defined by customer/order/raw material, etc

You can summarize the statistics according to different customers/orders/raw materials. Package including the yield, the proportion of each type of defect

Defects can be counted on a volume/sub-volume basis

You can filter, edit, validate, merge, etc. the inspection database in the reporting tool. to obtain the percentage of defective data that is of interest to the end customer

SPECIFICATION

- Detecting the width of 1250mm

- Maximum detection speed 550 m/min

- Detection accuracy 0.15mm*0.15mm

- Minimum spot detection size (dirty, ink spots) 0.2mm²

- Minimum line detection size (wire pulling, etc.) width ≥0.15mm,width ≥3mm

- Color difference detection △E≥2.5

- Overprint detection ±0.15mm

ADAPTATION